SOME OF OUR COMPLETED PROCESS AUTOMATION PROJECTS

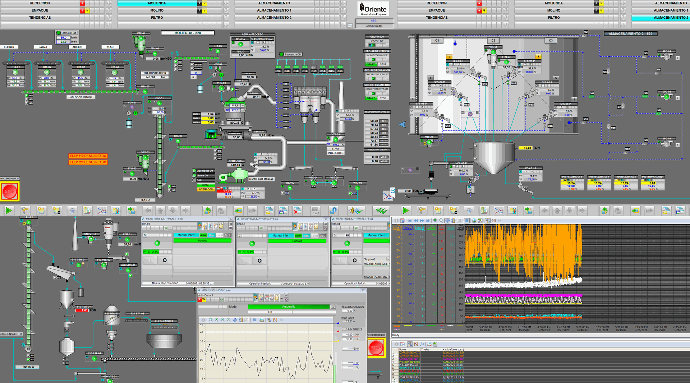

CEMENT GRINDING PLANT

Automation of a 30 Ton/h cement grinding plant. Manufacture and supply of control panels and DCS automation system with PCS7 and CEMAT. For the automation of this plant, specialized libraries for the cement industry were used. 740 digital inputs, 320 digital outputs and 88 analog inputs were programmed.

PROPANIL PRODUCTION PLANT

Supply of the entire DCS control system with SIMATIC PCS7 for the Propanil synthesis plant for a plant located in the Barranquilla free zone. For this project, everything from detailed engineering to manufacturing, implementation and comissioning of the plant was carried out. The project included the supply, installation and integration of 104 field instruments, 140 ON'OFF valves, installation of a fiber optic ring for the interconnection of remote stations, automated batch control. Throughout the project, more than 900 signals were handled. More than 4000 hours of engineering were used for the execution of the project.

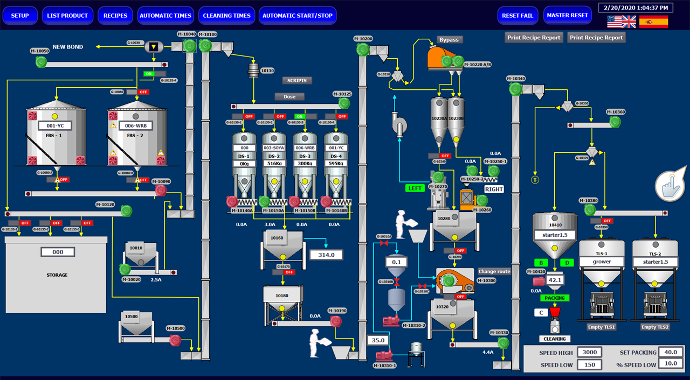

animal feed production plant (feed mill)

Located in Georgetown (Guyana), with a processing capacity of 10 tons/hour, intended for the production of animal feed from basic ingredients. Batch tracking capability and automatic dosing. For this project the electrical cabinets were manufactured and shipped together with the electrical materials for the entire electrical operation of the plant. Personnel were sent for the commissioning, training and 100% operational delivery of the plant.

UNLOADING OF BULK FROM SHIPS TO WAREHOUSES.

Automated control of ship unloading, using a 600 Ton/hour transport system. Automatic equipment start-up, sensors to avoid blockages, band misalignment, alarm and event log. Integration of the online weighing system with the general software of the port taking control of the inventory unloaded from the ship. This project included the manufacture of electrical cabinets, electric substation, complete electromechanical assembly, start-up of the scale, sensor installation and monitoring during the first operations of the system.

DRINKING WATER TREATMENT PLANT

Complete automation of a drinking water treatment plant to supply 3 municipalities in the south of La Guajira. Development of SCADA system for visualization and control of the PLCs that control the filters and chemical dispensers. Visualization of levels, flows and water quality. Pump start and stop control, automatic filter washing. Configuration and testing of all instrumentation.